Optosurf

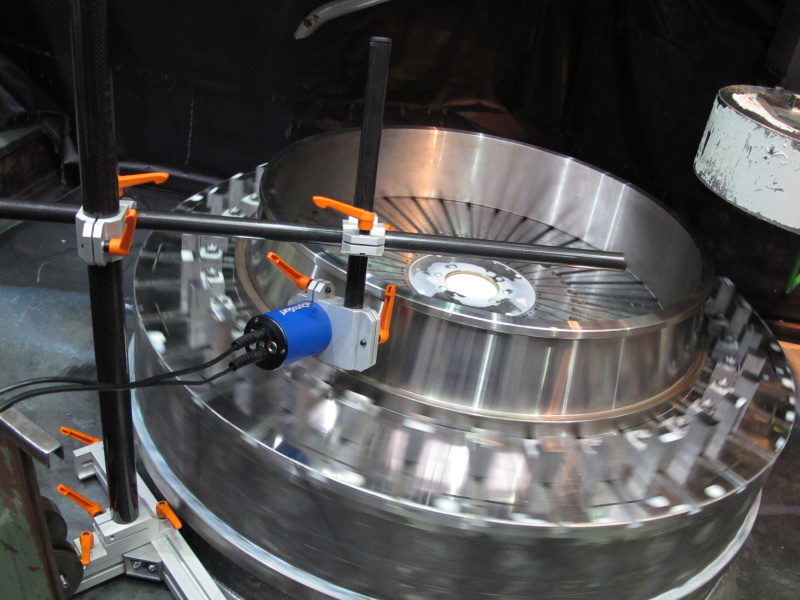

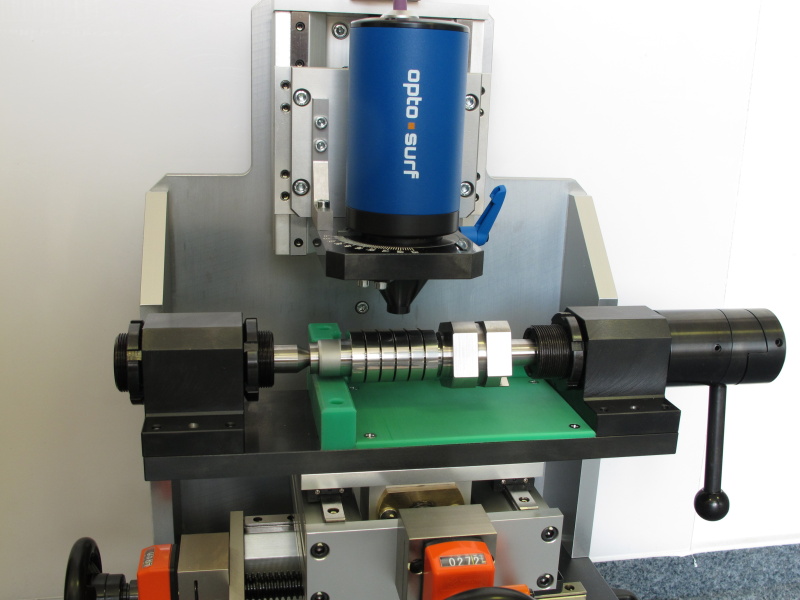

The German company Optosurf specializes in contactless surface measuring in the production. The measuring head Optosurf OS 500 evaluates the quantitative summary of the data about the microstructure of the surface. It evaluates the roughness, the waviness, the burned areas, ground joints …. The Optosurf sensor is able to perform up to je 2 000 surface measurings per second. All the measured data is saved and compared with the max value of the inspected parameter for evaluation to find out if the inspected piece is OK or NOK. The measuring sensor Optosurf can be integrated to both manual inspection devices (measuring devices) and to fully automated measuring systems (measuring devices).

The indisputable advantage of the measuring head Optosurf is the contactless surface inspection, the independence on a colour, the independence on the surface reflectance, nonsensitivity towards vibrations.

The measuring head Optosurf operates based on the method of scattered light. This method enables the evaluation of scattered light on the surface and it generates the roughness parameter, which is meant for the process in the range of Ra cca. 0,01µm - 1µm in corelation with the usual parameters Ra a Rz. The indisputable advantage of this method is the evaluation of the surface up to 0,9mm.

The measuring sensor Optosurf has a wide range of usage. Using this head we can inspect the surface of stud bal, geared rods, cranked shafts, cam shafts, rolled sheets, rods for shock absorbers, valves, bearing rings ….

Company website Optosurf